Sigma Design Company Introduces Sigma Industrial Water Group, Adds Two New Filtration Systems to Suite of Technology Solutions

Comments Off on Sigma Design Company Introduces Sigma Industrial Water Group, Adds Two New Filtration Systems to Suite of Technology SolutionsMiddlesex, NJ, July 14, 2025 – Sigma Design Company, a leader in the development of patented and innovative water conditioning components, filters, and systems, introduces the Sigma Industrial Water Group and adds two new systems that expand its portfolio of water and wastewater treatment product and solutions. This capability, which builds on more than 25 years of work in the water and wastewater sector, provides clients with fully customizable, engineered solutions for industrial water and nonhazardous wastewater challenges.

The Sigma Industrial Water Group specializes in the development of systems and technologies for industrial water reuse and recovery, separation and filtration, desalination pretreatment, ultraviolet (UV) disinfection, and the reduction of wastewater TSS discharge. The group builds all of its products to spec, ensuring that new systems meet each client’s unique requirements, and if it is building a component destined to be part of a bespoke water system, the group ensures that it can be integrated smoothly into the existing line.

The new systems are:

- The Model 4613 Automatic Tubular Backwash Filter System with 1-to-1500-micron Filter Elements, designed specifically to filter particulates from the fluid stream. Each filter housing contains a filter element with multiple tubes. To achieve finer filtration levels, each tube can be fitted with a 1-micron (1μ) up to 200-micron polymer filter sleeve. Multiplex units consist of anywhere from 2-20 individual tubular filters piped and valved in parallel to common inlet, outlet, and drain headers. Sigma’s advanced control system includes motor control and protection circuitry and constantly monitors the flow rate and different pressures across the entire system.

Model 4613: Automatic Backwash Tubular Filter System

- The Model 4614 UV + Automatic Prefilter Process Water System, which couples Sigma Industrial Water Group’s patented automatic water filtration technology with UV disinfection, a chemical-free water treatment process that uses ultraviolet (UV) light to kill or inactivate harmful microorganisms, including bacteria, viruses, and protozoa. It provides a highly effective, environmentally friendly, and easy to use solution for treating and disinfecting water in a wide range of applications and industries. Examples of applications include wastewater treatment and industrial water reuse and makeup water, while industries range from aquaculture to pharmaceutical production, electronics manufacturing, food & beverage, and other industrial markets.

Model 4614: Automated Prefilter and UV Water System for effective water disinfection

Additional Advancements

In addition to these two new systems, the Sigma Industrial Water Group has also developed these recent advancements that comprise part of the company’s suite of solutions:

- Model 4588 Ultra Filtration (UF) Brackish and Seawater Pilot System, a fully operational, engineered membrane system used to determine the effectiveness and sizing of full scale UF equipment projects

- Model 4583 High Solids Separation and Water Recovery System, which helps maintain peak efficiency and reduce downtime in industrial water processing challenges presented by heavily loaded water systems and the difficulties in managing high solids content

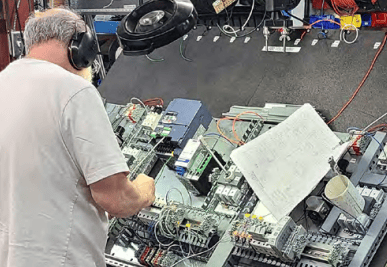

- Model 4615 Automated Industrial Backwash Filter Control System, a package that ensures that water filtration processes run smoothly, efficiently, and reliably, and its Differential Pressure (DP) Alarm Panel, a simple, easy-to-install, and configured solution to monitor the pressure drop across a filtration media or other pressure-sensitive processes. It is suitable for liquid and gas process systems. Using its HMI Touch Screen, the user can easily monitor inlet/outlet pressure on a continuously updating display with 0.1 PSI accuracy both locally and remote; dynamically adjust the DP alarm setpoint; and monitor the current DP up to 20 PSID.

A wealth of experience and expertise

With more than 25 years of work in the water industry, Sigma Design Company’s vast experience ranges from the development of filtration devices and media selection for solid/liquid separation, to flow analysis and modeling, industrial filtration systems and water treatment systems, filter component design and commercialization, filter housings (ASME VIII), and more. Focused on clients looking for water systems-related solutions, the company and its Industrial Water Group deliver cost-efficient, innovative, and highly effective designs and assembly solutions that meet each client’s unique business goals and leverage Sigma’s outside-the-box thinking. Its team of experienced filtration engineers provides expertise in filtration separation solutions and understands process limitations. Using advanced design tools and 3D visualization of fluid flow profiles, the company is able to uncover and remedy non-obvious, counter-intuitive design flaws.

“At Sigma Design Company, our commitment to innovation, excellence, and advancement never stops. We have been a trusted partner in design, engineering and manufacturing for many top international brands as well as prestigious universities and national governments since our founding. We’ve delivered over 1,000 successful design and design/build projects, on time and within budget, while saving our clients hundreds of thousands of dollars in manufacturing costs. We’ve worked with the world’s largest water product manufacturers and recognize the need for custom industrial water solutions in the areas of TSS reduction, water disinfection, automated prefiltration, and control systems,” said Gerard J. (Jerry) Lynch, P.E., Sigma Design Company’s President and CEO.

“Our expertise draws on more than 25 years of experience in developing water filtration systems for clients across a broad array of industries. Those decades of experience in engineering and analysis enable us to develop powerful water systems and technologies that meet our clients’ exacting needs. Whether clients require a full water filtration system, or want to develop a new water product or technology to integrate into their current filtration system, we have their needs covered from beginning to end,” he added.

About Sigma Design Company

Sigma Design Company is a single-source, vertically integrated supplier offering UL 508A-certified industrial controls and ASME-certified welding. Its in-house capabilities also include laboratory services such as internal flow testing up to 200 GPM, and its expert technicians and engineers can efficiently configure, analyze, design, and assemble fully customized solutions that suit each client’s project needs. Sigma Design Company has over 25 years of advanced engineering and FEA/CFD simulation experience in developing custom industrial water solutions. From concept to delivery, the company partners closely with each client to solve their complex water system challenges. All design, build and manufacturing is done at Sigma Design Company’s 20,000 square foot Technology Commercialization and New Product Manufacturing Center in Middlesex, New Jersey. For more information, contact info@sigmadesign.net.