Design and Engineering Services

Design and engineering services include new product development, complex mechanisms and machine design, 3D modeling, stress analysis, heat transfer analysis, flow analysis, patent support, manufacturing drawings, geometric tolerances and CAD drawings. We employ advanced engineering, simulation and rapid prototyping technology to speed time to market while helping clients reduce risks and costs associated with product development.

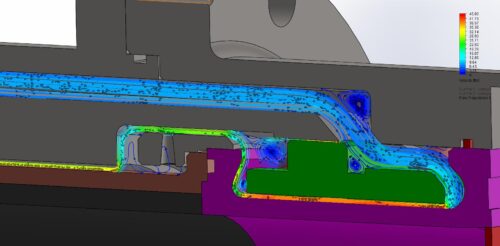

In addition to engineering new solutions, our team also evaluates products and systems under development, using advanced engineering analysis and rigorous testing protocols including simulation that allows us to uncover FEA and CFD stress, as well as flow and heat transfer to detect non-obvious, counter-intuitive design flaws early in the process.

Sigma Design also develops stringent test protocols and performs factory acceptance testing on all the electro-mechanical systems we build. Our broad manufacturing knowledge and experience helps streamline the process. Not only can we manufacture your systems; we can analyze and determine the best way to optimize them.

Sigma Design has

Sigma Design has  Sigma manages high end, high quality

Sigma manages high end, high quality  Sigma Design engineers are experts at using

Sigma Design engineers are experts at using