Sigma Design Company’s New Industrial Water Systems

Leave a CommentSigma Design has served as a trusted partner of many top international brands since our inception in 1999. We’ve delivered over 1,000 successful design and design/build projects on time and within budget. Among our many areas of industry and equipment expertise, we have over 25 years of experience developing water filtration systems. We’re excited to release our latest line of industrial water filtration systems.

Check Out Our Industrial Water Solutions!

Introducing New Industrial Water Systems at Sigma Design

At Sigma Design Company, our specialty lies in industrial water reuse and recovery, separation and filtration, desalination pretreatment, ultraviolet (UV) disinfection, and the reduction of wastewater TSS discharge. Our solutions can reduce or eliminate the labor needed for your existing water systems.

Sigma Design Company’s new industrial water systems target specific applications:

- Automated prefiltration systems for industrial water reverse osmosis (RO): for applications with variable TSS above 200 ppm

- Automated filtration and UV water systems: concentrating on TSS reduction and UV disinfection when needed

- Automated wastewater treatment systems for reverse osmosis: concentrating on TSS reduction

- Unique reuse systems with variable TSS filters and UV disinfection: concentrating on TSS reduction and UV disinfection when needed

Our designed, built, and tested systems include:

- Model 4613: Automatic Backwash Tubular Filter System

- Model 4614: Automated Prefilter and UV Water System

- Model 4615: Automatic Backwash Filter Controls System

- Model 4588: Ultra Filtration (UF) Brackish and Seawater Pilot System

- Model 4583: High Solids Separation and Water Recovery System

- Model 4577: Automated Extended Life Prefilter System

- Model 4570: Differential Pressure Remote Alarm Monitoring Panel

What Are the Benefits of Turnkey Industrial Water Filtration Systems?

To reap the full benefits of your water filtration project, work with a one-stop engineering company like Sigma Design. With complete project management capabilities, our experts can help you develop a new system from scratch or integrate new components into an existing filtration system.

With a variety of past successful projects to draw from, Sigma Design can build all products to your unique specifications. Examples of turnkey systems we produce include:

- Automatic Self-Cleaning Filters

- Automation and Monitoring Systems

- Disinfection Technologies

- Water Reuse Equipment

- Pumping Systems

- Mixing and Dosing Systems

- High Solids Separation

- Microfiltration

Why Work With Sigma Design Company for Industrial Water Filtration?

As a one-stop partner for engineering and manufacturing water systems, Sigma Design Company delivers cost-effective, innovative, and easily manufactured designs and assembly solutions based on each client’s unique business goals. We’ve worked with the world’s largest water product manufacturers and recognize the need for custom industrial water solutions in the areas of TSS reduction, water disinfection, automated prefiltration, and control systems.

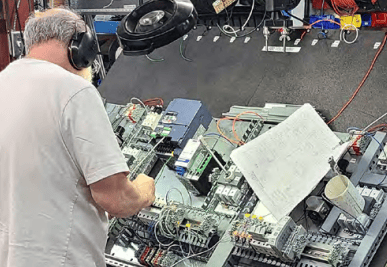

Sigma Design is a single-source, vertically integrated supplier offering UL 508A-certified industrial controls and ASME-certified welding. Our in-house capabilities also include laboratory services such as internal flow testing up to 200 GPM. Our expert technicians and engineers can efficiently configure, analyze, design, and assemble fully customized solutions that suit your project needs.

We have over 25 years of engineering and FEA/CFD simulation experience in developing custom industrial water solutions. From concept to delivery, we partner closely with you to solve your complex water system challenges.

Industrial Water Systems at Sigma Design

If you’re looking for custom industrial water systems that can help you achieve your specific business goals, Sigma Design is here to help. With over 25 years of experience in the industrial water space, we can assist in designing and building an entirely new custom system or seamlessly integrate new components into your existing system.

To learn more about our custom industrial water filter system capabilities, contact us today.