Customer: EPS Wastewater

Industry: Advanced Filtration and Non-Hazardous Wastewater Treatment

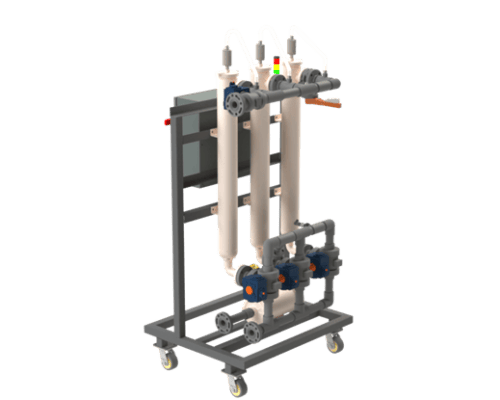

Sigma designs Automated Backwash Tubular Filter System

The Automated Backwash Tubular Filter System was originally designed for removing heavy particulates from the coolant used in grinding machines. The automated system constantly monitors the differential pressure between the influent and effluent manifolds. When the DP exceeds the operator defined setpoint on the HMI, the system will automatically trigger a backwash sequence. During the backwash sequence, the valves for the first filter will instantly switch to their backwash positions and the effluent valve will close. This valve change provides a quick “pop” with 2X the normal operating clean effluent flow being used to backwash the filter. After a short backwash, the valves will change states to backwash the next filter. Once all filters are backwashed, the effluent valve will open and everything returns to the normal operating state.

Services Performed:

Concept development, water purification system design, testing protocol, controls, sensors, electronics, complete fabrication including all controls, PLC/HMI, pipe and filter vessel welding, machining, validation, and testing.