Customer: Global Filter Manufacturer

Industry: Automotive Filtration

Sigma Design Company’s advanced engineering skills and experience using analytical software uncovers problem areas to save a client time and money.

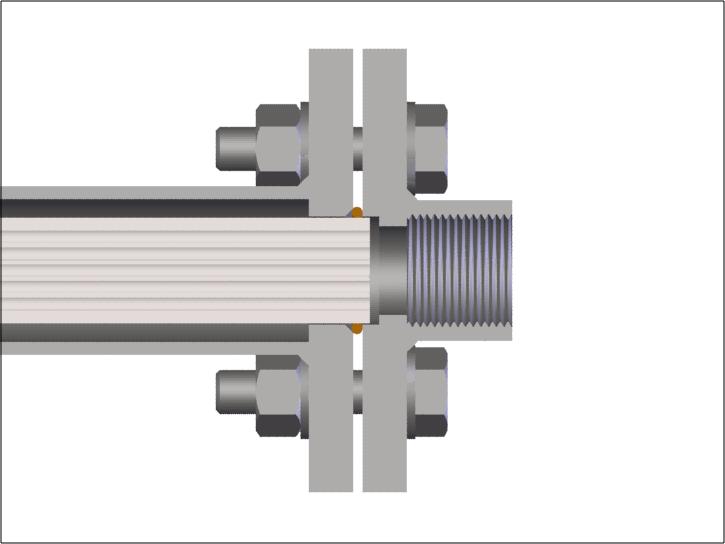

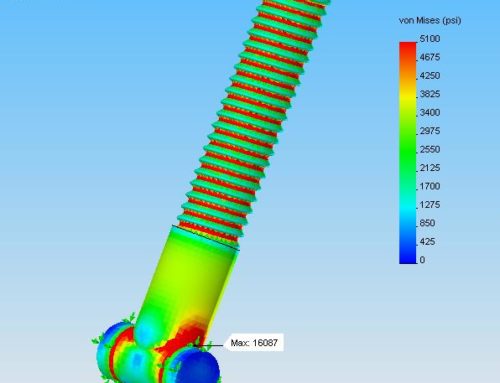

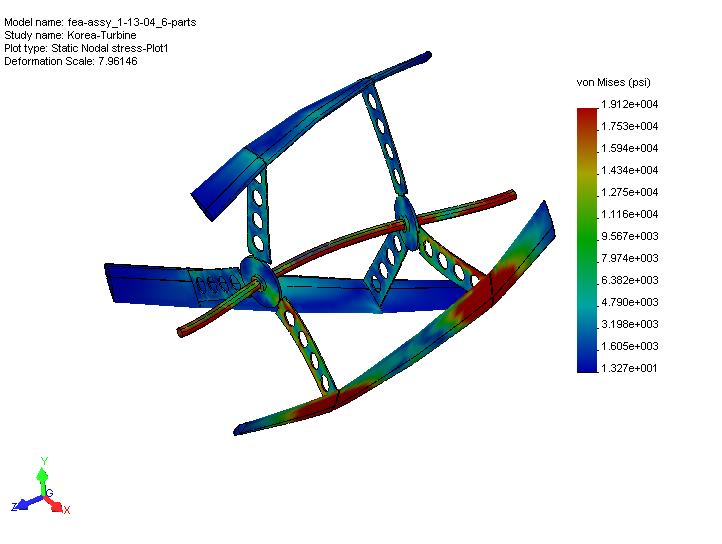

A globally known filter manufacturer had a fast-paced program and needed help to reduce their test program time. Starting with a first-pass iteration of a filter canister design, Sigma engineers used non-linear plastic simulation analysis to determine whether long-term cyclic loading would be likely to cause permanent deformation, and worse yet, failure. Sigma’s advanced engineering skills and experience using analytical software uncovered problem areas, which saved the client time and money. This insight got the client’s program back on track and on budget. Sigma’s engineering experience helps product launches stay on schedule by removing the unforeseen obstacles that delay new product development progress. Our team is capable of performing Linear Stress, Non-Linear Plastic Deformation, Computational Fluid Analysis, as well as using other specialized engineering software.

Services Performed:

Plastic Deformation and Stress Simulation, Detail Design Improvements, Design for Manufacturing, Product Development.