Seawater desalination systems use reverse osmosis (RO) technology in tandem with other systems to effectively separate water molecules and remove various contaminants. In a seawater desalination system, high pressures force raw water through thousands of semipermeable, tightly wrapped membranes. Smaller molecules pass through these membranes, leaving salt and other impurities behind. This process helps to combat water scarcity, creating a reliable and sustainable filtration alternative for producing potable water.

Sigma Design Company offers cutting-edge pre-filtration systems for seawater applications. These systems utilize automatic self-cleaning mechanical filters to protect the integrity of high-performance systems, including those that must process high solids or withstand unexpected increases in TSS loads. In this article, we’ll cover the key steps that make up the seawater desalination process. We’ll also highlight top-performing filtration solutions from Sigma Design Company and the numerous benefits they offer.

Seawater Desalination 101

Seawater desalination is critical for producing fresh water that meets strict quality requirements. It uses different eco-friendly technologies and designs to create a sustainable water solution that businesses around the world can implement. Learn more about this innovative process below.

The Desalination Process

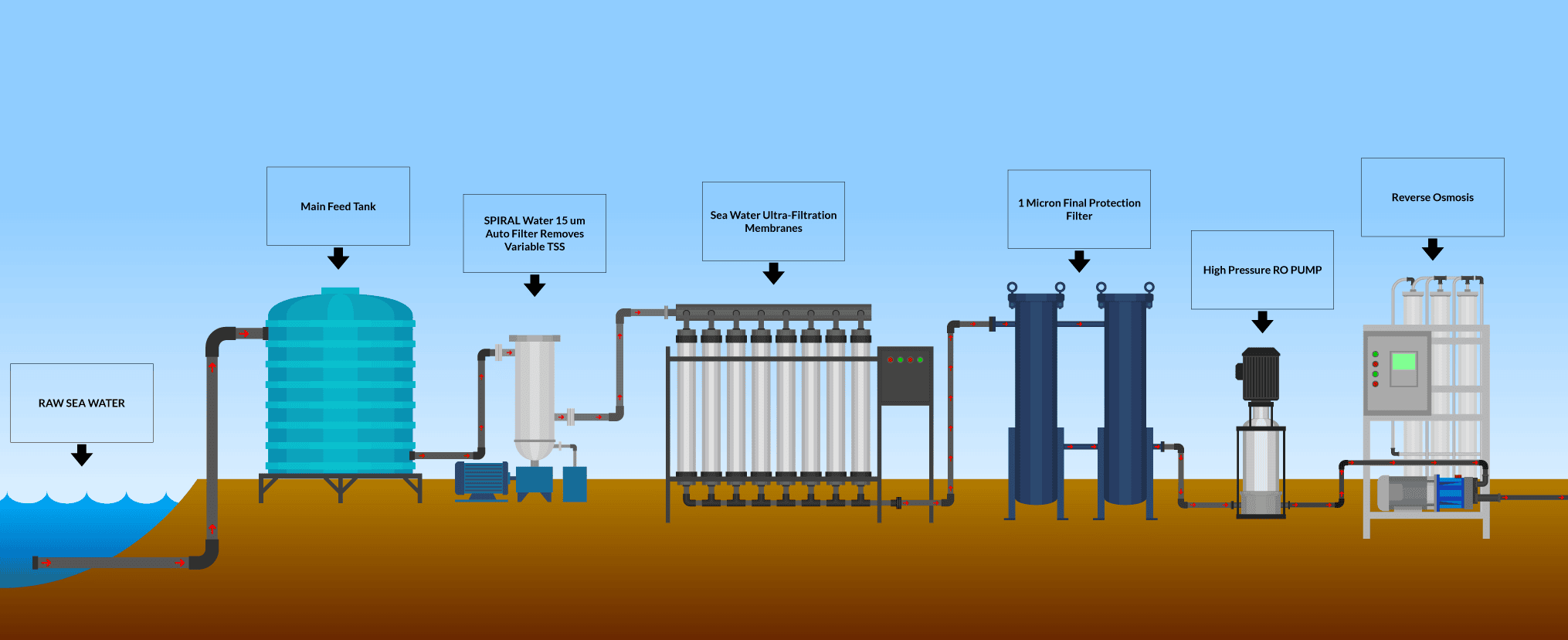

There are several major steps in seawater desalination. From pre-treatment to PLC control, each plays an important role in producing fresh water at scale:

- Water intake. The first step is to collect water for treatment. An intake system sucks water in and then sends it into a saltwater reverse osmosis plant.

- Pre-treatment. During pre-treatment, filters efficiently treat water for seawater desalination, removing residual substances such as microorganisms, suspended solids, and colloid particles. Using a 15-micron self-cleaning filter system with a PVDF UF filtration system can enhance inert corrosion resistance while allowing for automatic operation of raw feed water containing as high as 2,000 ppm. Additionally, our polishing 1 um high-flow filters can significantly reduce NTU.

- Reverse osmosis (RO). RO systems complete the conversion process. The semi-permeable membrane effectively separates salt from the water through the necessary osmotic pressure, removing up to 98% of TDS to purify water.

- Chemical dosing. Chemical dosing equipment comes with dosing pipes, a dosing pump, and a chemical tank. Installing this equipment at the center allows for easy cleaning, supervision, maintenance, and operation.

- CIP cleaning. Routine chemical disinfection and cleaning of the RO membrane is key to maintaining optimal performance. Teams can use specialized cleaning mechanisms with a filter, tank, and pump to clean the membrane’s surface.

- PLC control. Performance testing software can be used to regulate process meters and system performance, notifying users of potential system faults or upcoming maintenance needs.

Benefits of Seawater Desalination Systems

Seawater desalination systems offer numerous advantages over conventional methods, providing industrial applications with the following:

- Additional water sources. Seawater desalination is ideal for applications with limited groundwater and rainfall surface water sources.

- Improved water quality. This sustainable water solution produces fresh water while adhering to heavily regulated industry standards.

- Environmental conservation. Seawater desalination can significantly reduce the need for surface water diversion or groundwater extraction, protecting natural ecosystems and limiting ecological impact by utilizing available water resources.

- Drought resilience. Seawater desalination is essential for industries and communities that require a drought-resistant source of fresh water.

- Economic growth. Desalinated water can be used for many industrial, agricultural, and municipal purposes while supporting substantial economic growth.

Sigma’s Ultra Filtration (UF) Brackish and Seawater Pilot System

Sigma Design Company offers the Model 4588 Pilot Ultrafiltration (UF) System for brackish and seawater applications. This precision-engineered, fully operational membrane system can be used to assess the effectiveness of full-scale UF projects.

Our polyvinylidene fluoride (PVDF) hollow fiber UF membrane modules are ideal for seawater applications frequently exposed to extreme conditions, producing higher-quality water at a cost similar to traditional filtration techniques. This is due to the numerous inherent chemical and physical properties found in PVDF UF membranes, which include the following:

- Chemical resistance. PVDF membranes offer impressive resistance against harsh chemicals and can tolerate the use of stronger cleaning agents. They can also remove scaling and biofouling in water with varying pH levels.

- Mechanical strength. These high-performance membranes also offer impressive strength, maintaining functionality in variable pressures found in seawater environments.

- Thermal stability. PVDF membranes can operate in high temperatures, making them useful in areas where seawater temperatures tend to be higher.

Our UF membrane systems can serve as highly effective tools in various filtration processes, including:

- Microorganism and particle removal. A finer pore size enables UF systems to effectively remove bacteria, particulate matter, viruses, and other pathogens from brackish sources when producing potable water.

- Pre-treatment for seawater desalination. UF is commonly used in seawater desalination processes like reverse osmosis (RO) as a preliminary treatment step. This limits the fouling of RO membranes by eliminating microorganisms and small particles. In turn, operators can improve filtration when water passes through the RO system. Pre-treatment for seawater desalination can also extend the lifespan of RO systems.

UF membrane systems can also greatly reduce the Silt Density Index (SDI) of water. This test measures the particle content of water flowing through the purification system to determine the likelihood of membrane fouling. A lower SDI value indicates a lower particle content, while a higher SDI value indicates potential clogging and degradation of RO membranes.

What Makes Sigma Different

Sigma’s control systems offer unmatched protection in multi-filter processes. Our patented automated filtration systems are capable of managing TSS of over 500 ppm when compared to traditional self-cleaning filters, automatically managing upset conditions (up to 5,000 ppm) without operator assistance. Their robust mechanical cleaning design is ideal for applications requiring filtration finer than 75 microns. Our filter systems are suitable for applications requiring solids concentration and conditioning (i.e. for feedstocks). They can operate at system pressures as low as 10 psig with no pulsing, and our retrofits do not require additional pump modifications.

Thanks to their impressive performance, self-cleaning filters from Sigma also offer the following advantages over time:

- Extended filter life

- Reduced maintenance costs

- Improved filtration efficiency

- Optimized system performance

- Reduced downtime

- Improved filtrate quality

Our filter systems have the smallest footprint in the industry. They are modular, scalable, and easy to maintain. Our water recovery solution maintains a continuous filtrate of 99% with smart controls that allow for reliable automated filtration (from 15 to 1,000 microns).

About Sigma Design Company

For over 20 years, Sigma Design Company has been a leading one-stop design and manufacturing resource for engineered systems and specialty equipment, including advanced water filtration systems for brackish and seawater applications. Over the years, we have used our expertise and innovative thinking to realize more than 1,000 successful projects for clients all over the world. Our experienced team strives to provide affordable, creative, manufactured designs and assembly solutions that help clients achieve their long-term business, revenue, and product goals.

Contact us today to learn more about the benefits of working with Sigma Design Company and see how we can help meet the needs of your next project.