Differential Pressure Alarm Systems

The new SIGMA DP Alarm Panel is ready to satisfy your Differential Pressure monitoring needs. The Differential Pressure (DP) Alarm Panel is a simple, easy-to-install, and configured solution to monitor the pressure drop across a filtration m

Using our HMI Touch Screen, the user can easily:

- Monitor inlet/outlet pressure on a continuously updating display with 0.1 PSI accuracy both locally and remote.

- Dynamically adjust the DP alarm setpoint

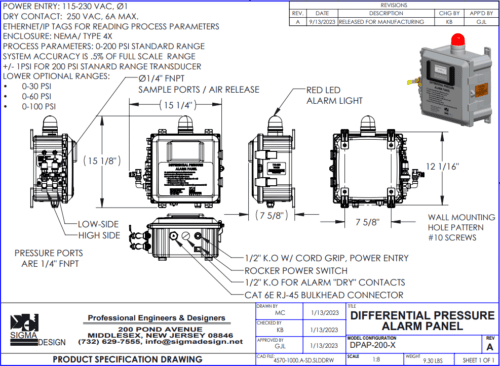

- Monitor the current DP up to 20 PSID. A red LED stack light will turn on when the current DP pressure exceeds the setpoint value. The light can be configured to turn on solid or blink. An optional audible alarm module can be added for non-visual indication. Additionally, a “dry” set of relay contacts will close (Ø1, 6A, 250 VAC). These contacts can be used to power ancillary equipment or remotely communicate with other industrial systems.

View our Differential Pressure Alarm Panel Flyer!

Differential Pressure Alarm Panel Cutsheet

Benefits of Using Differential Pressure Alarm Systems:

Monitoring differential pressure is crucial in process applications for a number of reasons, including:

Safety: Differential pressure measurement can also play a vital role in ensuring the safety of a process. By monitoring pressure differentials, operators can take immediate action to prevent accidents, equipment damage, and potential harm to personnel.

Efficiency: By monitoring differential pressure with the SIGMA DP Alarm Panel, you can assess the efficiency of the fluid process and identify potential issues such as blockages, leaks, or flow restrictions. This information can help optimize the process to ensure that it operates at its maximum efficiency.

Quality Control: In industries where precise control of fluid flow is essential for maintaining product quality, monitoring differential pressure becomes critical. Deviations in pressure can indicate changes in the composition, viscosity, or density of the fluid being processed, which can affect the quality of the end product. Regular monitoring with the SIGMA DP Alarm Panel allows for quick detection and correction of any issues that might compromise product quality.

Process Control: Many industrial processes require precise control of fluid flow rates to achieve desired outcomes. Using the SIGMA DP Alarm Panel, operators can adjust control valves and other equipment to maintain the desired pressure differentials, thus ensuring that the process operates within the specified parameters. Equipment Health Monitoring: Changes in differential pressure can often signal equipment wear and tear or clogging. By regularly monitoring pressure differentials across filters, heat exchangers, and other components, maintenance teams can schedule preventive maintenance activities, reducing the likelihood of unexpected breakdowns and downtime.

Energy Efficiency: In systems where pumps and compressors are used to maintain fluid flow, monitoring differential pressure with the SIGMA DP Alarm Panel can help optimize energy consumption. Regulatory Compliance: Is your industry subject to strict standards related to process conditions? Differential pressure measurement can provide documentation of compliance by demonstrating that pressure differentials are being maintained within specified ranges.

Troubleshooting: When an issue arises in a process, differential pressure measurement can provide valuable diagnostic information. The SIGMA DP Alarm Panel can detect sudden changes in pressure, which can help operators identify the location and nature of the problem, enabling faster troubleshooting and resolution.

SCALE DIFFERENTIAL PRESSURE ALARM PANEL PRODUCT SPECIFICATION DRAWING, Click to Download

Differential Pressure Solutions by Sigma Design Company

At Sigma Design Company, we recognize that monitoring differential pressure in process applications is essential for maintaining process efficiency, ensuring product quality, ensuring safety, controlling processes, monitoring equipment health, optimizing energy usage, complying with regulations, and troubleshooting issues.

We have designed and manufactured the SIGMA DP Alarm Panel to provide critical insights that enable operators to make informed decisions and take timely actions to keep the process running smoothly and safely.

For more information about the SIGMA DP Alarm Panel, contact info@sigmadesign.net or Call 732-629-7555.

Let Sigma Design Company be your One Stop Shop for Engineering Solutions.