Sigma Design is celebrating their 22nd anniversary under current ownership. However, the company’s origins go back much further, originally founded in 1962 as a machine design firm by brothers Murph and John Abraham. Machine design became a tougher and tougher gig as the manufacturing sector in New Jersey, and nationwide for that matter, started to contract through the 80’s and 90’s. The Abraham brothers had started seriously considering closing shop. Sigma’s current owner, Jerry Lynch, knew the brothers for some time. As fate would have it over a friendly lunch, they mentioned that if the right buyer came along, they would probably sell the company. Entrepreneurship had been a lifelong dream for Jerry, an engineer by trade with decades of experience in manufacturing. The idea of taking a company that was established but struggling and in need of a new vision appealed to Jerry and the acquisition was complete in early 1999.

Sigma Design began under new ownership as it had ended under the former ownership, strictly a design firm with no manufacturing capabilities. Jerry could see the trends, as well as the desire by current customers to have a design firm that was also engaged in the manufacturing and production process. Customers wanted a one stop shop that could produce their designs, rather than just deliver the detailed design and manufacturing package. The ability for a single company to fully design and draft, then pilot, test, debug and refine a piece of equipment became strongly in demand. Many large manufacturers do not have the internal resources dedicated to refining and perfecting engineered systems. This ultimately led to the foundation of the Sigma Design of today, when in 2011 they purchased a 20,000 sq-ft facility to afford means to manufacture their designs.

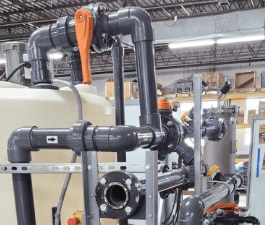

Sigma continued their evolution once they had room to work. Since acquiring the new facility they have gained capabilities in all facets of manufacturing. Sigma has a full weld shop offering qualified welders in TIG, MIG and SMAW process as well as a CNC machining area. They have a fully tooled assembly area which can accommodate electrical control panel fabrication and large electro-mechanical assemblies. Drawing on an area of expertise of their owner, Sigma formed a partnership with Spiral Water Technologies. This necessitated a 200 GPM water filtration system test loop that is now a fixture in the Sigma Shop.

One area where Sigma Design excels is with advanced engineering and analysis. Sigma caught on early to the 3D modeling FEA trend and has engineering expertise to use these tools. Performing stress analysis, heat loading, fluid flow etc. in a digital environment helps their customers visualize their designs and adapt to design conditions before manufacture, and more importantly, service in the field. These tools also aid with material selection and manufacturing process layouts. Sigma has become an expert ally for their customers in using these tools on both Sigma Designs, as well as finding non-obvious challenges with customer supplied designs. Jerry along with his smart, creative staff has transformed the business into a single-source provider of design, analysis and manufacturing services of new products, equipment, and machinery.

As Sigma heads towards the future, they are gaining momentum and stronger than ever. They have started to establish themselves as a reliable design and manufacturing partner for large, international companies. This has led to an aggressively growing work history, especially with repeat manufacturing work of large devices and pieces of equipment. Sigma will continue to evolve, learn, and enhance their business model as their company grows into 2021 and beyond.

Posted in Advanced Engineering Analysis, Company News, Made in New Jersey, Made in USA, New Product Development, People, Press, SIGMA Capabilities