Customer: Global Specialty Metal Manufacturing Firm

Industry: Material Manufacturing

A global metal manufacturing firm needed Sigma Design Company to reverse engineer and model a heat exchanger.

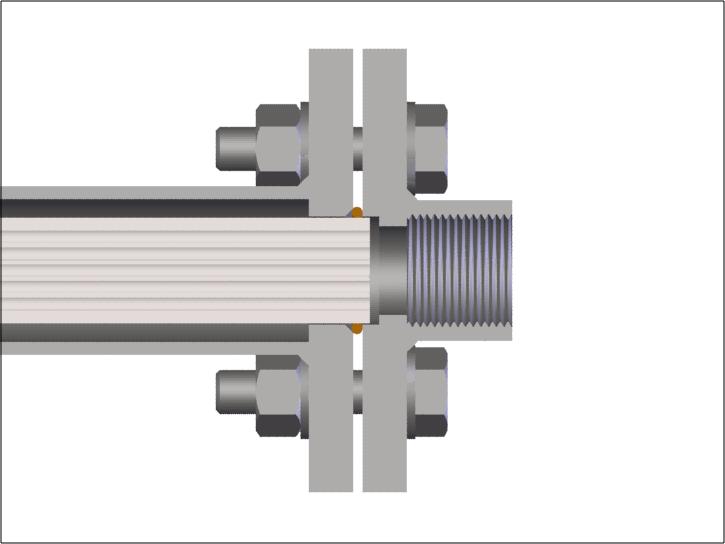

A global metal manufacturing firm needed Sigma Design Company to reverse engineer and model a heat exchanger that is used in a foundry for creating alloy steel bars. In this application, hot metal flows in from one side, at 2800 °F, and is cooled by water that enters in from the other side. When the metal exits, it will be solidified to 1700 °F. The water and metal never touch, and because of the high heat, the heat exchanger itself had some very complex geometry and materials. Sigma was tasked with this project because of their engineering and design experience.

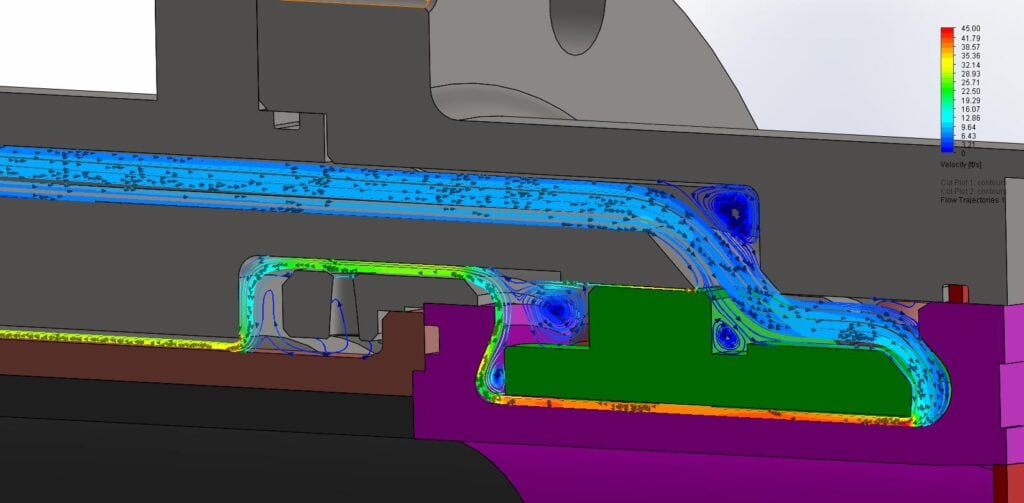

A SolidWorks Simulation CFD was run to determine the fluid flow profile. By running the simulation with different configurations of the heat exchanger, we could see which configuration provided better flow and therefore better system temperature control. We created areas where the flow rate could be measured, and used that data to determine the proper orientation of the components. Sigma is also the manufacturer of the modified cooling system components.

Services Performed:

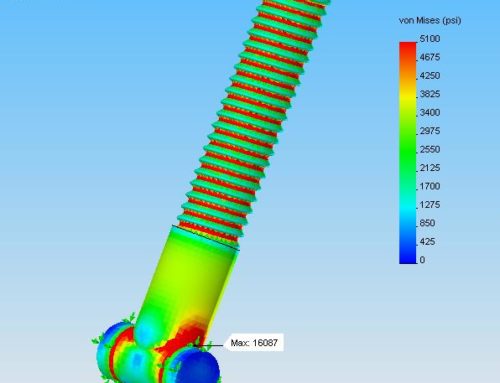

Engineering services, concept development, FEA & CFD analysis and simulation, detail system design, fabrication, assembly and testing.