Industrial Water Filtration Systems

Sigma Design Company, a leader in pioneering patented and innovative water conditioning components, filters, and systems, also provides clients with fully customizable, engineered solutions for industrial water and nonhazardous wastewater challenges. Since 1999, our work within this industry has encompassed filtration devices and media selection for solid/liquid separation, flow analysis and modeling, industrial filtration systems and water treatment systems, filter component design and commercialization, filter housings (ASME VIII), and more.

Our experienced filtration engineers have expertise in filtration separation solutions and understand process limitations. Using advanced design tools and 3D visualization of fluid flow profiles, we are able to uncover and remedy non-obvious, counter-intuitive design flaws. Sigma Design has decades of experience in engineering and analysis, and we have the ability to develop water technologies that fit your exact needs. Whether it is a full customized water filtration system or you require development on a new water product or technology to integrate into your current filtration system, we have you covered from beginning to end.

Learn more about the different types of industrial filtration systems, their benefits, and Sigma Design’s capabilities below.

Our Suite of Industrial Water Solutions

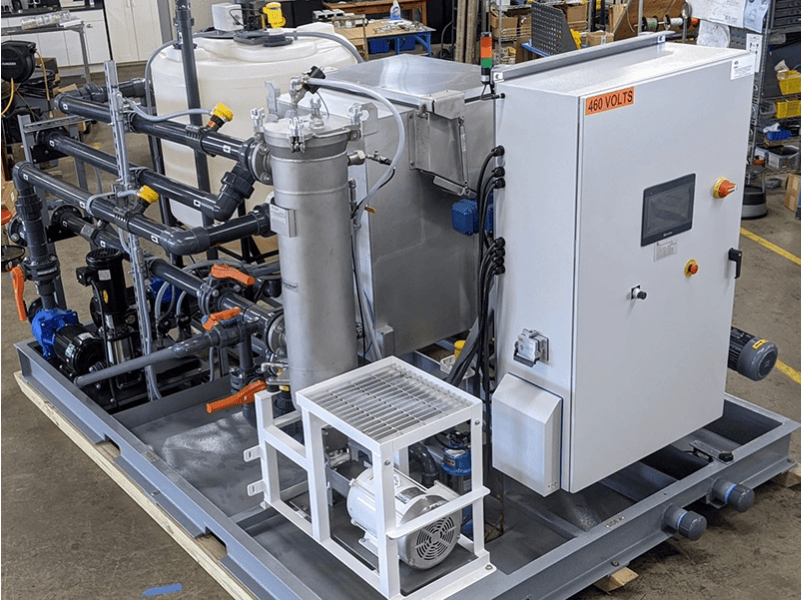

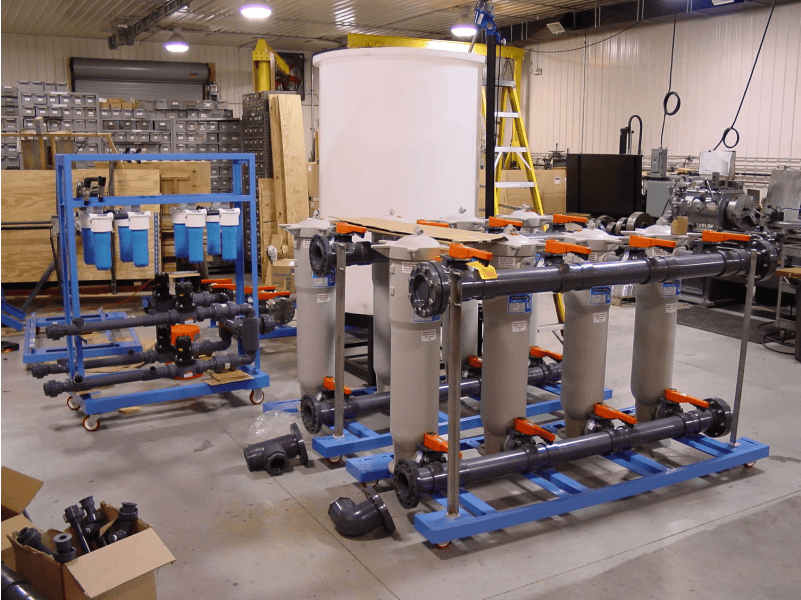

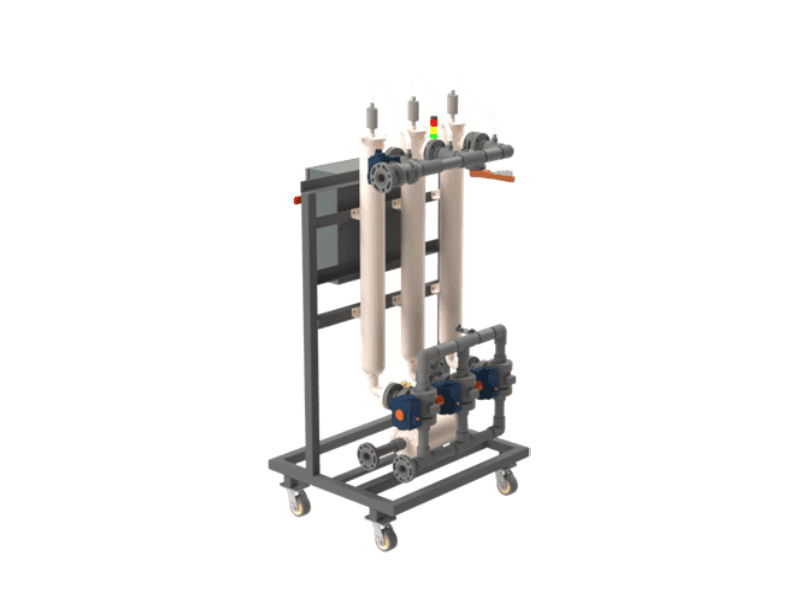

With Sigma Industrial Water Systems, you can select and integrate a range of advanced technology components into your project to meet your exact needs. We build all of our products to spec; this ensures that new systems meet your unique requirements, and if we are building a component of your water system it can be integrated smoothly into your existing line.

See below for examples of our technologies to see our different areas of experience. At Sigma Design, we work directly with you to figure out your exact needs to custom tailor a solution that fits your exact applications.

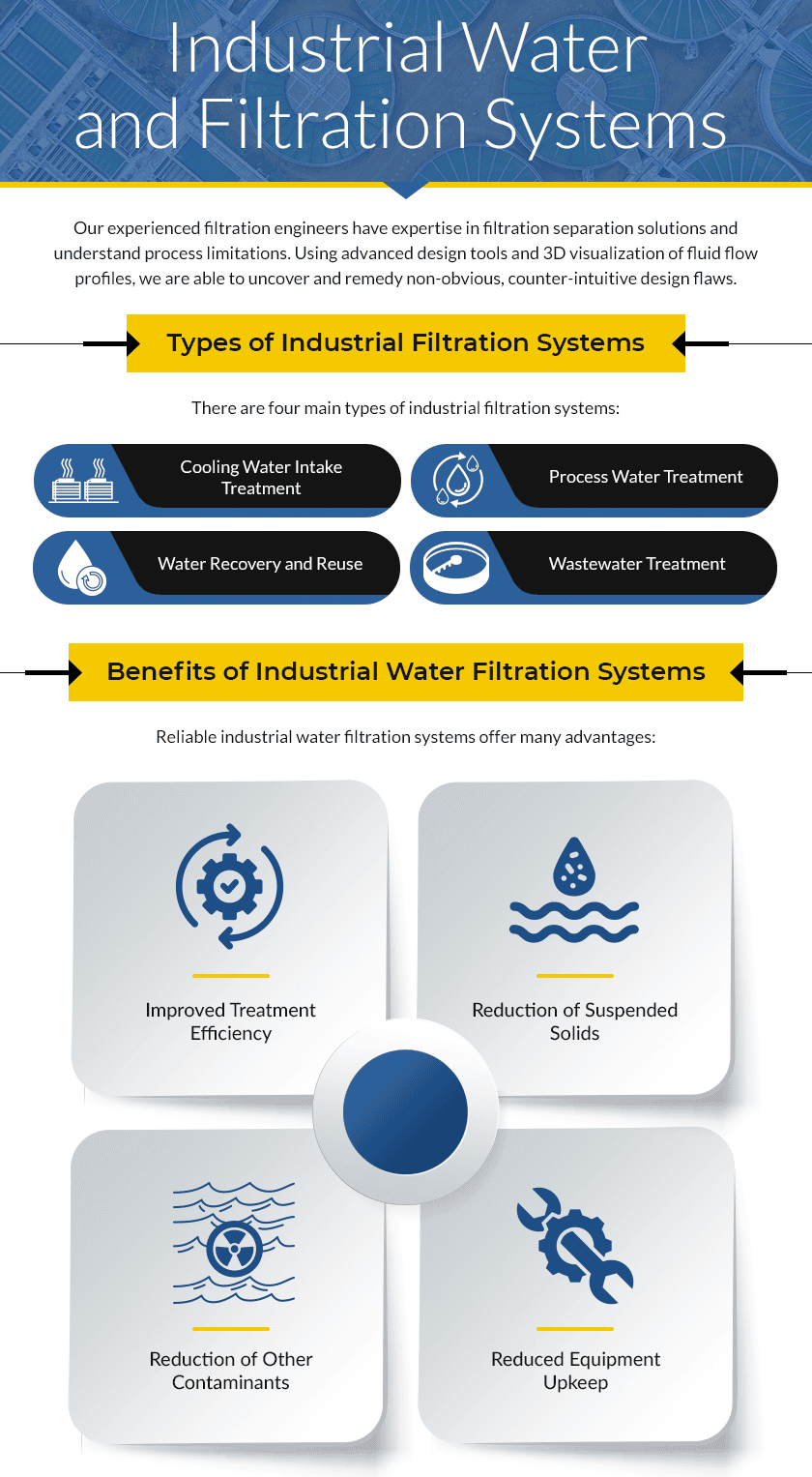

Types of Industrial Filtration Systems

- Automated Self-Cleaning Pre-Filter Systems for handling variable TSS non-traditional water sources

- Automated Pump & Treat Solutions for Water Reuse Systems targeting zero liquid discharge (ZLD)

- Automatic Prefilters & UV (Ultraviolet) Disinfection Systems for effective water disinfection

- Automated Self-Cleaning Low Micron Filter Systems for precision filtration

- High Solids Water Processing Solutions including conditioning, dewatering, and filtration

- Smart Automated Filter Process Controls Systems for optimized performance and efficiency

Our Industrial Water Filtration System Capabilities

When needed, we can provide a consultative approach to help clients along every phase of building a new filtration system. This includes designing, 3D modeling, testing, prototyping, and manufacturing.

Our experience and capabilities in industrial filtration and water treatment include:

- Design/build an arsenic removal pump and treatment system (MEI)

- Design/build an in-situ water analysis system (Well Tech Environmental)

- Design/build a pilot automatic filtration system for the CVNX Desalination Systems (U.S. Navy)

- Develop testing systems to evaluate desalination equipment on naval vessels (U.S. Navy)

- Design/build a complete automatic filtration and separation product line (Spiral Water Technologies)

- Design/build Nutrient Dosing System for Vertical Farms (Crop One)

- Develop a patented centrifugal separator with an ultraviolet disinfection system (University of Maryland Center for Environmental Sciences)

- Design cooling water filters for zebra mussel control at the Hoover Dam and Parker Dam (U.S. Bureau of Reclamation)

Industrial Water and Filtration Product Design and Manufacturing Case Studies

Industrial Water Solutions by Sigma Design Company

Since 1999, Sigma Design has delivered over 1,000 successful products and solutions to clients in diverse industries, saving them hundreds of thousands of dollars on manufacturing. Our expertise and dedication to excellence have allowed us to work with global brands, prestigious universities, and national governments. Our industrial water filtration and treatment systems utilize the latest in water technology to meet your project’s exact needs.

If you have any questions about our capabilities, contact us today.