One-stop Design, Engineering & Manufacturing

ASME & AWS Certified Welding

New Jersey-based, owned and operated, Sigma Design Company continues to be a dynamic and trusted manufacturing partner for businesses in the state and beyond. Not only are we focused on executing every client engagement seamlessly, on time, and budget; we are also intent on helping to expand manufacturing in New Jersey by leveraging our experience, knowledge, and customer-centric approach.

For 25 years, we have helped transform our clients’ ideas into highly effective product solutions. To date, we have delivered more than 1,000 successful design and design/build projects while saving our clients hundreds of thousands of dollars in manufacturing costs.

When President and CEO Gerard (Jerry) Lynch purchased the original Sigma Design Company in 1999, it was a small four-person machine design company. Within three years, the firm had evolved into a design-build shop, and just a year later, we were managing a number of projects for leading global companies as well as the US Navy.

Ag-Tech and Food Processing Equipment

We continue to build on that success. Every day, we strive to live up to our well-earned reputation as a trusted, one-stop, cost-effective resource for all aspects of product design and development, manufacturing, and validation, helping satisfy our clients’ business and revenue goals whether they are a start-up or major multinational brand.

Today, our global operations are located in a state-of-the-art 20,000 square foot Technology Commercialization and New Product Manufacturing Center in Middlesex, New Jersey, home to a complete manufacturing team plus advanced engineering services all under one roof.

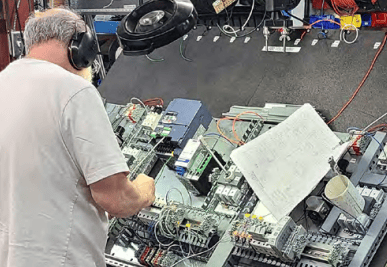

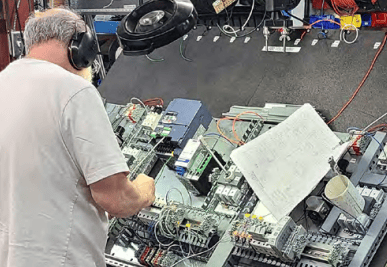

UL508a Certified Electrical Enclosure and Panel Building

Our vast experience and expertise enables us to serve clients across a wide array of industries: ag-tech, food processing, clean energy & power generation; health & life sciences, water systems & filtration, culinary appliances and more.

As we celebrate our 25th anniversary, we remain committed to continuous improvement in all aspects of our operations, investing in the latest technologies and in our people with each team member a specialist in their field. We invite you to contact us to learn more about what sets us apart and how we can help you.

New Jersey-based Sigma Design is a leading one-stop design, engineering, and manufacturing resource for the development of specialty equipment and engineered systems. Our clients have included hundreds of leading global brands and manufacturing firms across a wide array of industries, transforming more than 1,000 design and design/build projects into successful products and specialty equipment in use across the world.

Testing and validating product is of paramount importance no matter what industry you are in, and this often requires specialized equipment and processes. When it comes to industrial lubricants, it is critical to ensure that these products will provide the advertised level of protection for the equipment to which they will be applied.

Viscosity is a key metric specifically for lubricants, which is defined as a measure of a fluid’s resistance to deformation at a given rate. In simple terms, viscosity is a fluid’s “thickness”.

This can get complicated when it comes to lubricants in high friction applications such as an automotive engine or a turbine spindle. As heat rises due to friction, a lubricant’s viscosity, and thus its wear protection, will decrease. Knowing how effective your grease will be at room temperature and in operation is critical for manufacturers and consumers alike.

Sigma Design recently developed a lubricant test machine for a global petroleum company, one of our valued customers, to measure changes in viscosity of grease over a several hour-long trial. This rotating equipment is loaded with large, greased bearings and spun at several hundred RPM. The equipment is designed to measure the resistance of the grease between a driven top-half and idler bottom-half of the bearing chamber. The resulting force is displayed on a simple and reliable analog gauge that can be viewed and logged throughout the test. Our equipment provides a simple solution to a crucial need.

Sigma Design has developed and built analytical, testing and validation equipment for dozens of our customers across a wide variety of industries. From consumer product testing to cellular research, Sigma Design has been a valued and trusted manufacturing partner of equipment for over 20 years.

Customer: Free Flow Power, MA

Industry: Alternative Energy

Sub Heading: Sigma Design Develops a State of the Art, Run of River, Hydrokinetic Electric Generator.

Hydrokinetic River Turbines Capture Alternative Energy.

Sigma was approached by a Boston venture group who needed to develop a pilot renewable energy hydrokinetic generator system. It was a pivotal milestone for the ventures funding and they needed this fully submerged run of river device in the water and producing electrical energy in 6 months from our first meeting. In addition to the accelerated timeline, the project provided us with several other challenges. Most notably being the power generating electronics, hydrodynamic balancing, and marine submersion anti-fouling prevention. In the end we were successful in that the system was designed, manufactured and installed. In fact we understand that it is still running deep in the Mississippi River north of New Orleans.

Sigma Design led the Development, Manufacturing and Testing. Development Partners: Turbo Solutions, VT and AEC, NY

Sigma Design led the Development, Manufacturing and Testing. Development Partners: Turbo Solutions, VT and AEC, NY

Services Performed:

Concept Development, Flow Simulation, Detail System Design, Electronics, Fabrication and Testing.

Service Menu

Customer: NAVSEA

Industry: Industrial Power Systems

Sigma Design supports U.S. Navy shipboard defense systems

Sigma was very excited to work on another project with the U.S. Navy. Talk about a project in ‘our wheelhouse’ as they say. Jerry Lynch, a ‘tin can sailor’ who served as a destroyer GMG2 gunner was thrilled to have the opportunity to work on this special project supporting shipboard defense systems for Navy operations.

Michael Collins, the lead engineer on the NAVSEA project worked for the U.S. Navy in Philadelphia before coming to Sigma. This project requires the creative design of safety features while providing 50% more power through their hydraulic power supply system. With operating pressures in excess of 3000 psi, the pressure compensation and hydraulic shock suppression systems were key features in the new design. This HPU joins the growing roster of Sigma’s products designed and built in NJ. Sigma is proud to have the opportunity to work with the Navy to improve operational shipboard defense systems used around the globe but made in NJ.

Services Performed System engineering, detail design, CAD drafting, electronics, welding services, machining and fabrication, testing & start-up, system training, and on-site validation.

Service Menu

Sigma Design led the Development, Manufacturing and Testing. Development Partners: Turbo Solutions, VT and AEC, NY

Sigma Design led the Development, Manufacturing and Testing. Development Partners: Turbo Solutions, VT and AEC, NY