Industrial Art Produces Alternative Energy

University Collaboration for Water Treatment

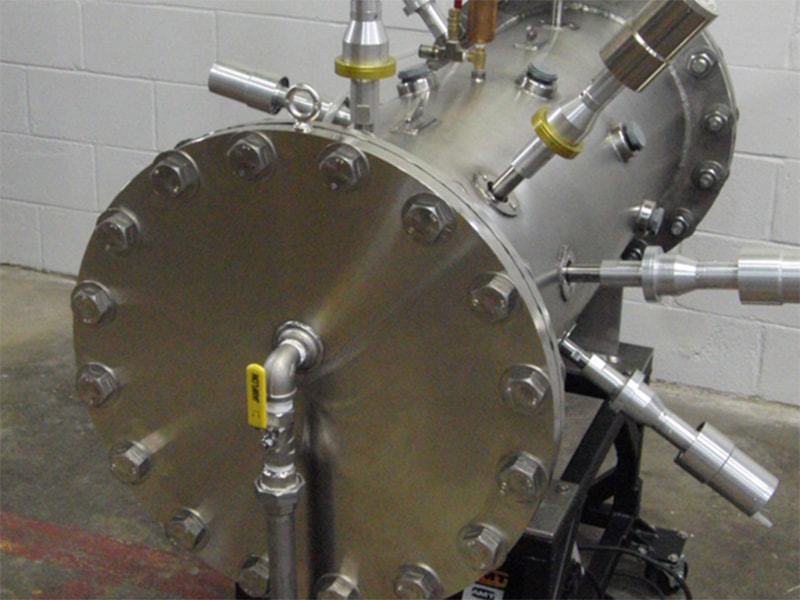

Sigma manages high end, high quality build/assemble/test projects for manufacturers. These projects work best on equipment requiring a higher engineering focus than simple machine shop parts do. As a manufacturer’s assembly resource, Sigma’s goal is to reduce costs of manufacture by reducing parts, reducing weight and removing design flaws.

“Our customer was impressed with the trolley assembly…. Thanks again to you and the staff. I’ll be sure to keep you folks in mind for the next project…Nice Job!” Senior Systems Engineer – Instrument Manufacturer

Decades of Manufacturing Engineering Experience: LET SIGMA BUILD IT!

A Sigma Manufacturing Success Partner:

Several years ago, a manufacturing company turned to Sigma to manufacture an optical diagnostic device originally costing $18,000 per unit to manufacture. Our goal was to reduce costs of manufacture. After Sigma built the first unit, each cost was reviewed and the product was value engineered to reduce the future price while improving reliability and accuracy. This iterative process was performed again and again until now, after two years of improvements (and continuous production), today’s cost of supply from Sigma to the customer is 45% less than the original costs.

How did we do this? By working closely with the client’s project engineer, Sigma was allowed to control the design and work with its own suppliers. We found ways through structural FEA analysis to make less obvious design changes to reduce parts, reduce weight and reduce costs to make the device easier to assemble and test. The finished product delivered from Sigma is a fully tested, packaged assembly.

This client’s commitment has allowed Sigma to order larger quantities of parts to maximize economies of scale and further lower costs. In accordance with the client’s Lean KANBAN stocking levels, Sigma now keeps the product in stock ready to fill orders as needed. Sigma does all the procurement, QA/QC, deburring, finishing, polishing, CMM dimensional checks, assembly, labeling, lubricating and “burn-in”. It’s as simple as that.

Experienced with:

- Transitional motion driven stage development X-Y-Z

- Motors: Piezo, Stepper, Servo

- Heat Management: cold fingers, peltiers, cold plates, heat sinks

- Optic and Image Capture

- LED Light Source

- Specialty Light Curtains

Sigma provides manufactures with

- in-house design engineering

- in-house professional manufacturing

- skilled engineering staff ready to design top-notch solutions

- a project management team to ensure that all project goals are met on time and on budget

Download related information: Design-Build Engineered Systems & Machines