There’s a good chance that if you are a snacker, you have tasted a ‘popped’ chip. These snacks can be sweet, savory, or salty bites derived from corn, rice, potato, chickpeas or other combinations of starches. The starches are formed into micro pellets, which are then “popped” using high temperature and pressure to create snack ‘chips’. Since no frying or baking is required, a popped snack gives the impression of being a healthier choice. While that’s a discussion for another time, we do know that the snack business is expected to grow steadily as consumers look for variety in their snack options. Competition among producers for space in the snack aisle is fierce. With that, the equipment needed to produce a quality product to meet that demand is critical. Currently, most of the equipment manufacturers are located in Europe or Asia.

Sigma Design’s Engineered Solution

A local U.S. business contacted Sigma Design Company to inquire about manufacturing a better pop machine, here in the U.S. The company was finding it difficult to meet demand with their existing machinery and was desperate for design improvements. This project required the type of unique and custom problem-solving solutions for which Sigma Design Company is known. The Sigma team knew their design experience would create a machine with improved operator access and result in cycle time reduction, increased chip output, and reduced changeover time. After many months of discussion and hammering out the details, the customer was still reluctant to take that ‘leap of faith’. We get it. Companies come to Sigma Design Company to solve difficult and confounding design problems. Each one is a custom project and often not easy. Convinced that the snack machine had potential, Jerry Lynch, owner of Sigma Design Company said we seem to be at a stand-off here, let’s make this machine even though the customer was not yet all in and prove we have the skills they need.

A local U.S. business contacted Sigma Design Company to inquire about manufacturing a better pop machine, here in the U.S. The company was finding it difficult to meet demand with their existing machinery and was desperate for design improvements. This project required the type of unique and custom problem-solving solutions for which Sigma Design Company is known. The Sigma team knew their design experience would create a machine with improved operator access and result in cycle time reduction, increased chip output, and reduced changeover time. After many months of discussion and hammering out the details, the customer was still reluctant to take that ‘leap of faith’. We get it. Companies come to Sigma Design Company to solve difficult and confounding design problems. Each one is a custom project and often not easy. Convinced that the snack machine had potential, Jerry Lynch, owner of Sigma Design Company said we seem to be at a stand-off here, let’s make this machine even though the customer was not yet all in and prove we have the skills they need.

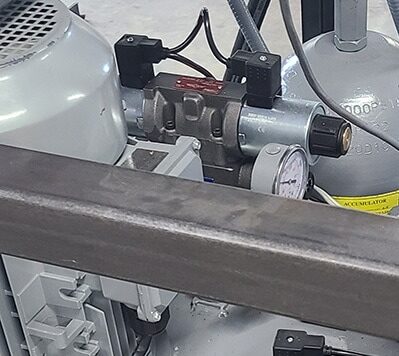

Hydraulic Power Unit

Pop Chip Dies